Turret Lathe!

Hey, remember how I was going to automate that Enco aftermarket turret, which would then be fitted to a South Bend 16" lathe?

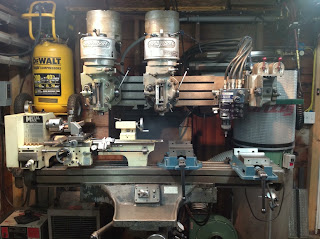

Well, scratch that. We just got an actual turret lathe instead. Look at this beautiful beast:

It's a Warner & Swasey No. 4 Turret Lathe. It's 8 feet long, 5 feet tall, and weighs about 4000lbs. The above image is the lathe while it was a the shop that we acquired it from, Nasin Machine Co. in Moosup CT.

The Warner & Swasey Company of Cleveland Ohio has a very interesting history. Worchester Reed Warner and Ambrose Swasey, the founders, were icons of the New-England machine-tool building industry during the industrial revolution. Starting at Exeter Machine Works in Exeter, NH, the two then went to work at Pratt & Whitney (in the company's early days, it was a machine-tool builder) where they managed and developed novel and improved methods of accurate gear manufacturing. For that reason and others, their story is close to my heart, and I am proud to acquire a piece of their legacy.

The below images are of the lathe once we got it home and cleaned it up a bit. I have images of how we moved this beast and got it to our second-floor shop space which I will post later.

It's 15" swing over the bed, 8" swing over the carriage, but the reason I picked up this model is the 2.5" through-spindle capacity. You can stick a 2.5" round steel bar in one end, and just crank out parts all day long. Gear blanks here we come!

This beast is powered by a dual-speed 7.5hp Louis Allis 3-phase induction motor. The first time we wired up the motor and turned it on, the friggen thing sounded like a jet engine spooling up. It was terrifying and amazing; my two favorite qualities in machine tools.

There is one little kink about the electrical demands of this motor though. Originally a 220-volt single-voltage motor, at some point it was rewound for 550-volt, single-voltage. That's an odd number; 3-phase service around here is basically always 208, 220, 240, or 480-volt, and so we are having to rig something special to supply this 550-volt motor. I briefly considered using this motor as "my first motor re-winding project", but after stacking up the costs for magnet wire, fish paper and resins (mostly the cost of magnet wire), I decided that we should instead take advantage of a derelict 30kva delta-star-conversion isolation transformer that we already had kicking around the shop. 7.5hp ends up being something like 9kva, so the transformer is more than happy to supply that. Having a 30kva transformer (which is ~400lbs and is the size of a mini-fridge) supply this lathe is definitely a bulky arrangement, but it will do for now.

More on the current state of this lathe, and it's electrical work, coming soon!

For now, here's a picture of Andrew Birkel with the Warner & Swasey No. 4. Andrew did all of the cleaning on this machine, and has been an immensely helpful right-hand man for my machinery salvaging activities, for a very long time.

Well, scratch that. We just got an actual turret lathe instead. Look at this beautiful beast:

It's a Warner & Swasey No. 4 Turret Lathe. It's 8 feet long, 5 feet tall, and weighs about 4000lbs. The above image is the lathe while it was a the shop that we acquired it from, Nasin Machine Co. in Moosup CT.

The Warner & Swasey Company of Cleveland Ohio has a very interesting history. Worchester Reed Warner and Ambrose Swasey, the founders, were icons of the New-England machine-tool building industry during the industrial revolution. Starting at Exeter Machine Works in Exeter, NH, the two then went to work at Pratt & Whitney (in the company's early days, it was a machine-tool builder) where they managed and developed novel and improved methods of accurate gear manufacturing. For that reason and others, their story is close to my heart, and I am proud to acquire a piece of their legacy.

The below images are of the lathe once we got it home and cleaned it up a bit. I have images of how we moved this beast and got it to our second-floor shop space which I will post later.

It's 15" swing over the bed, 8" swing over the carriage, but the reason I picked up this model is the 2.5" through-spindle capacity. You can stick a 2.5" round steel bar in one end, and just crank out parts all day long. Gear blanks here we come!

This beast is powered by a dual-speed 7.5hp Louis Allis 3-phase induction motor. The first time we wired up the motor and turned it on, the friggen thing sounded like a jet engine spooling up. It was terrifying and amazing; my two favorite qualities in machine tools.

There is one little kink about the electrical demands of this motor though. Originally a 220-volt single-voltage motor, at some point it was rewound for 550-volt, single-voltage. That's an odd number; 3-phase service around here is basically always 208, 220, 240, or 480-volt, and so we are having to rig something special to supply this 550-volt motor. I briefly considered using this motor as "my first motor re-winding project", but after stacking up the costs for magnet wire, fish paper and resins (mostly the cost of magnet wire), I decided that we should instead take advantage of a derelict 30kva delta-star-conversion isolation transformer that we already had kicking around the shop. 7.5hp ends up being something like 9kva, so the transformer is more than happy to supply that. Having a 30kva transformer (which is ~400lbs and is the size of a mini-fridge) supply this lathe is definitely a bulky arrangement, but it will do for now.

More on the current state of this lathe, and it's electrical work, coming soon!

For now, here's a picture of Andrew Birkel with the Warner & Swasey No. 4. Andrew did all of the cleaning on this machine, and has been an immensely helpful right-hand man for my machinery salvaging activities, for a very long time.

Comments

Post a Comment