Cylindrical Grinding on a Surface Grinder

How do I do cylindrical grinding? For a long time, the grinding capability that I have was limited to a 6" x 18" Boyar-Shultz surface grinder. I saw my lack of cylindrical grinding capability to be a problem that I would at some point or another, need to confront, considering that I make a lot of gears, and gears often need to go on shafts that are of a precise diameter.

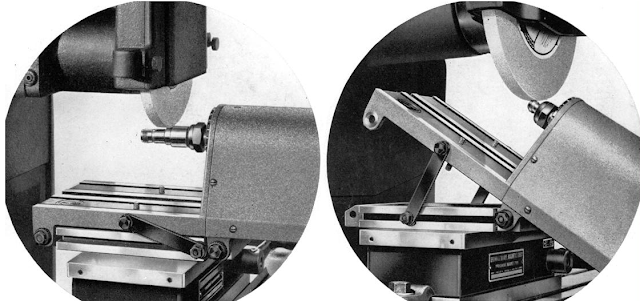

My 'get-by' solution was to acquire one of these nifty things:

This is a 'Cylindrical Grinding and Indexing Attachment No. 616' made by Brown & Sharpe. I had known that this class of 'motorized, between-centers' fixture had existed, and finally I found someone in northern New Jersey, selling one on craigslist.

Lathes.co.uk has a great article about this fixture: Brown & Sharpe No. 616 Cylindrical Grinding and Indexing Attachment

Lathes.co.uk has a great article about this fixture: Brown & Sharpe No. 616 Cylindrical Grinding and Indexing Attachment

With this setup I can easily achieve diameters within one ten-thousandth of an inch (0.0001").

Here's a video of using the fixture, to grind a custom motor rotor shaft, for a high speed brushless dc motor:

If the embedded video doesn't work for any reason, the video is on my youtube channel, "Reeve Gear":

https://www.youtube.com/watch?v=bDD018mDZDM

Thanks for reading!

Comments

Post a Comment